Our Founding Story

One of the most fascinating things about Brighton NC Machine Corporation is our journey from humble beginnings. Established in 1965, our company started with three families and a single NC lathe. The founding families would rent the lathe and the building in which they produced products and fulfilled client orders.

A year later, they would purchase their first NC milling machine — a monumental move that demonstrated the founders’ tenacity and vision for the company’s future. By 1971, Brighton NC Machine Corporation would launch its own product line of press overload devices. The early 80s marked a period of exponential growth with land purchases and facility construction.

The rest of the 80s and 90s saw even more exemplary progress with contracts with Caterpillar, a tool rebuild program, and the evolution toward becoming a fully-fledged CNC machine company. Brighton NC Machine Corporation would go on to win numerous awards during the late 90s and 2000s.

WHAT WE STAND FOR

- ISO 14001

- ASR Certificate of Registration for Precision Lathe, Mill, Grinding Operations, and Assembly

- ISO 9001

- AVU Registrations Certificate for Precision Lathe, Mill, Grinding Operations, and Light Assembly

- IATF

- PSI

- NIST Compliance

These certifications, coupled with our awards, showcase our commitment to innovation, quality, and progress.

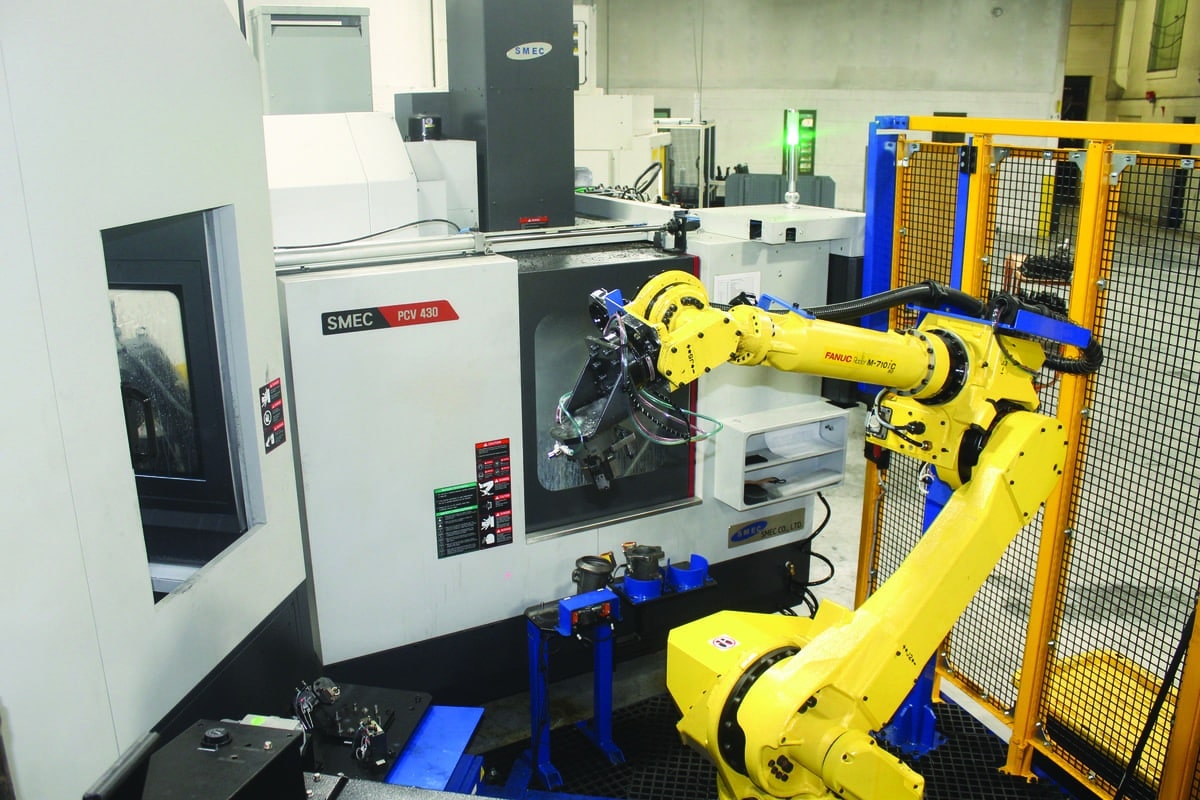

In fact, adaptiveness and innovation make up the core of our forward-thinking company. Our team never shies away from adopting cutting-edge manufacturing technologies or paving the way for newer, faster production methods.

Our Services and Expertise

Our modest beginnings made Brighton NC Machine Corporation a force to be reckoned with. We’ve risen to every challenge our industry and customers presented. Therefore, we carved our place in various industries, including:

- Military and defense: The military demands high-quality, heavy-duty machinery. We consistently deliver.

- Class 8 trucking: Modern society depends on reliable diesel and large-engine trucks. We manufacture the backbone for many class 8 trucks, like drag links and steering.

- Construction: Construction customers such as Caterpillar rely on us to design and build products that meet their high standards and needs.

- Automotive: Automotive manufacturers have unique demands to keep their vehicles safe, efficient, and up to consumer standards. Something you should know about Brighton NC Machine Corporation is that most major vehicle producers trust us.

MEET THE TEAM BEHIND OUR SUCCESS

Two of the three original founding families still have an influential hand in leading Brighton NC Machine Corporation toward growing success. They developed a leadership team that carefully crafted a skilled staff of long-standing workers who consistently pushed the envelope of what supervisors and customers could expect. Jack Clausnitzer is one such prominent figure who helped bring BNC where it is today.

He thoroughly outlined machining fundamentals, passed the knowledge on to subsequent employees, and helped other leadership members craft our current training techniques. This knowledge-sharing and mentorship has led to a team of almost 200 employees, many of whom have worked with us for nearly 40 years.

Our talented, knowledgeable machinists operate over 70 CNC machines and tools. Their commitment to excellence and unwavering product quality has contributed to our current company culture that elevates continuous improvement, learning, and skill mastery.

OUR COMMITMENTS

Our commitment to excellence extends far beyond the quality of products that earn customer loyalty. We also extend our values and hunger for success to our surrounding communities and environment through charitable donations and work with the Gleaners Community Food Bank of Livingston County in Brighton, Michigan. Our team assists with the organization’s Victory Garden project to feed less fortunate locals.

We also implement sustainable manufacturing practices to make the world we all share an eco-friendlier place.

LOOKING AHEAD: OUR FUTURE VISION

One lesson we’ve learned from our shared history and past experiences is to focus more on the present and plan for the future. Our leadership team is always open to integrating innovative methods, developing new products, and venturing into different industries to improve our customers’ experience with us. If you want to learn more about Brighton NC Machine Corporation, contact us about your vision and how you think we can help.