Brighton NC's Services the class 8 truck Industry

Brighton NC's Past Work in the class 8 truck Industry

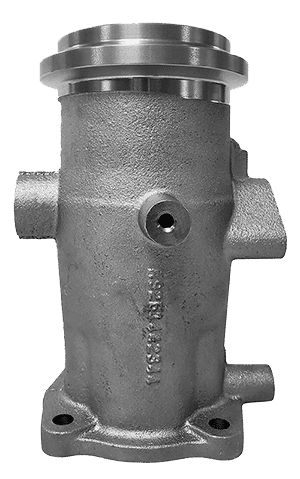

RAM 2500/3500 Emergency Takeover

- The Fiat Chrysler supplier was failing to produce acceptable drag links and steering arms for the HD Pickup launch.

- Fiat Chrysler’s Crisis Response Team came to BNC for a ‘temporary’ solution.

- BNC had the first part in production, with PPAP, two weeks after award.

- BNC ended up producing ten part numbers for the duration of the program.

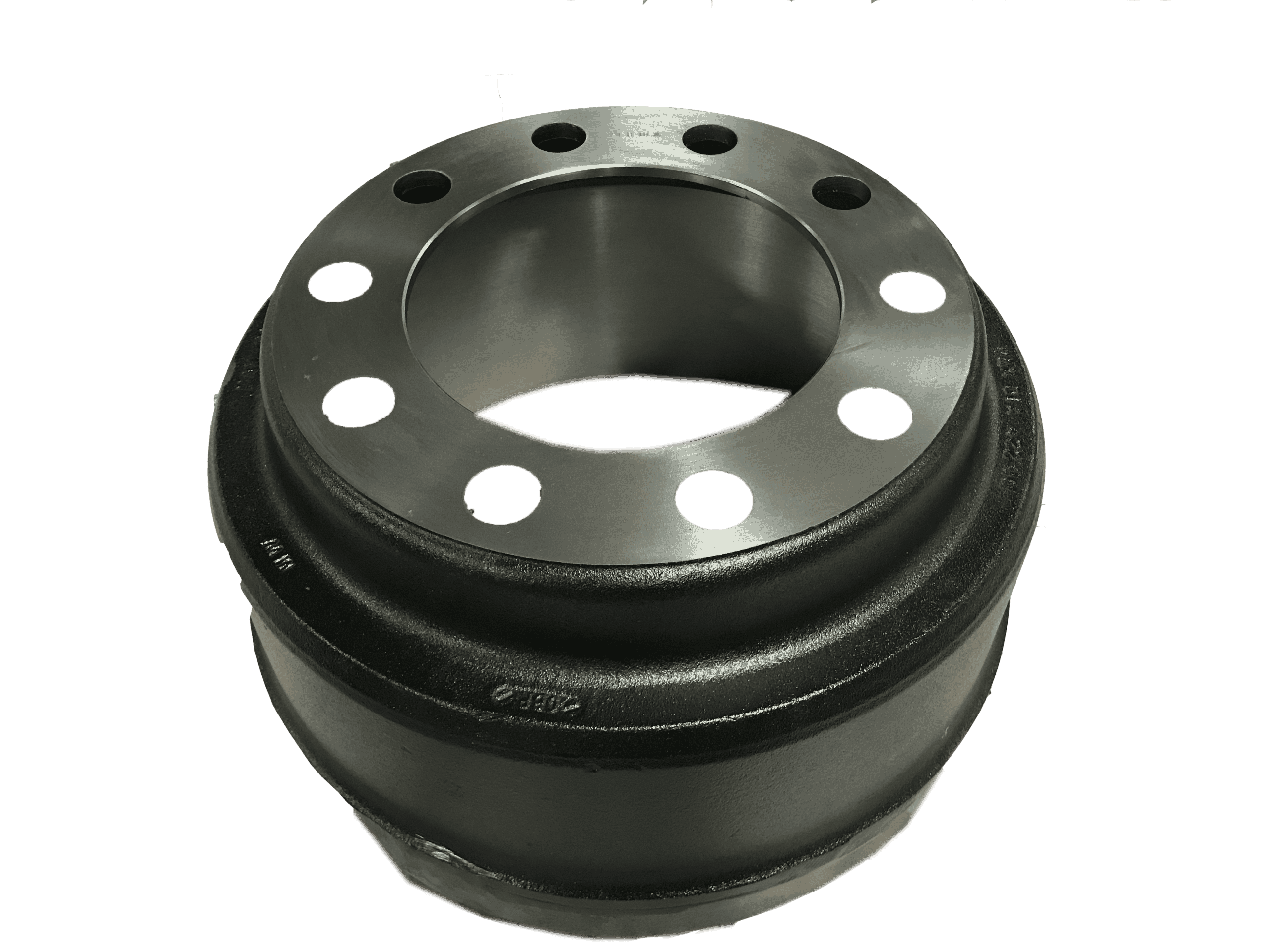

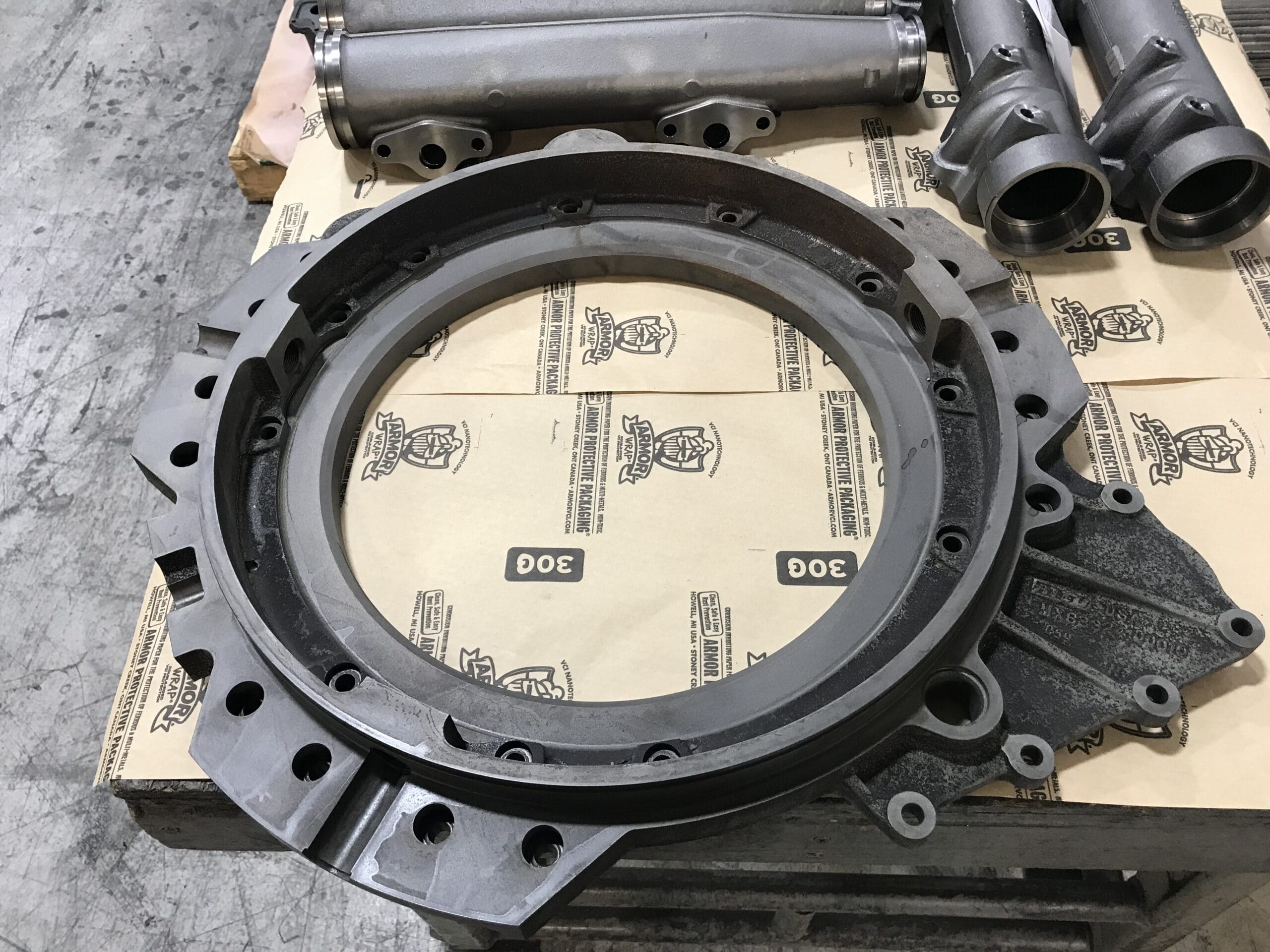

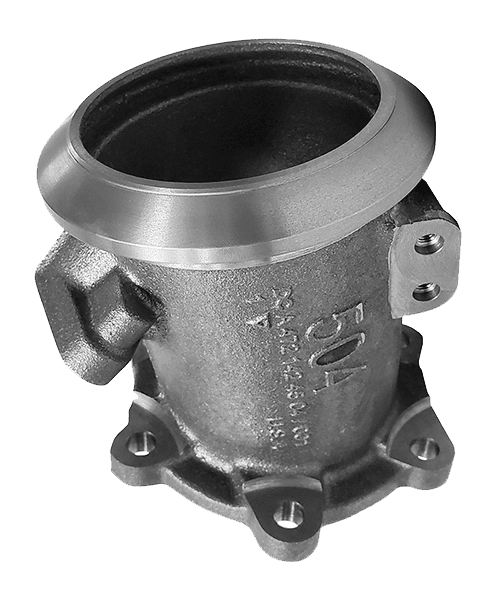

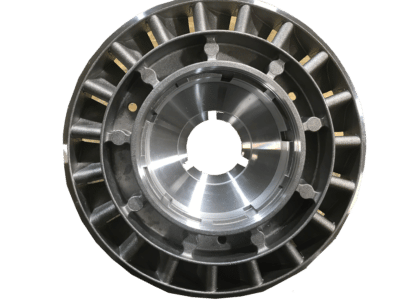

DDC Flywheel Emergency Award - Heavy Truck

- BNC historically has produced a large percentage of DDC flywheels, but we were not awarded the 2020 flywheel program.

- The supplier selected by DDC was not able to meet production demands.

- BNC was contacted in November 2020 to produce the flywheel.

- BNC was able to PPAP and supply production parts with in two weeks of award.

- Additionally, BNC designed and built a custom bearing press for this project, since lead times from manufacturers would not meet the DDC timeline.

- Process includes turning, shrink fitting ring gear, milling, balancing, and installing bearing.

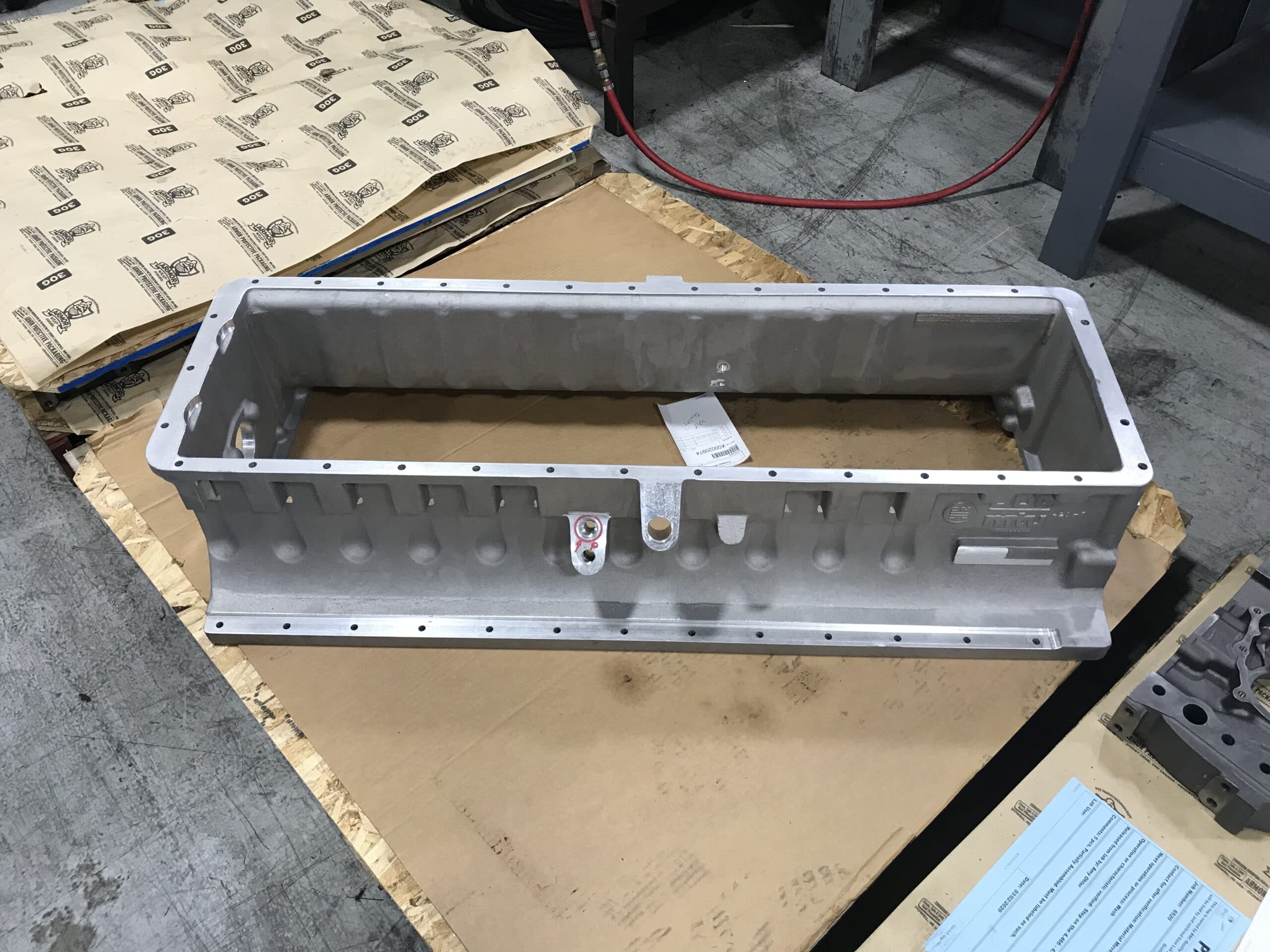

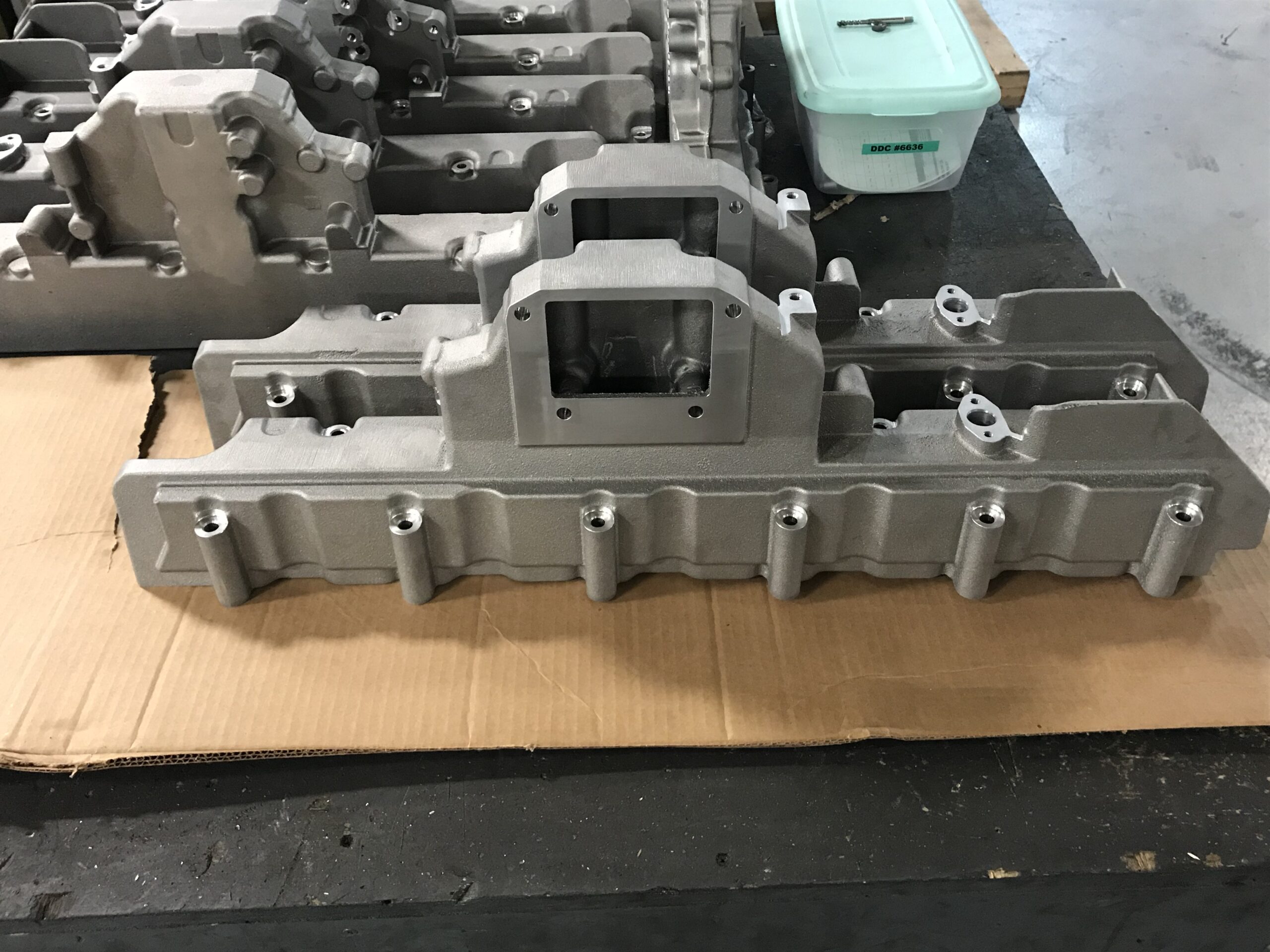

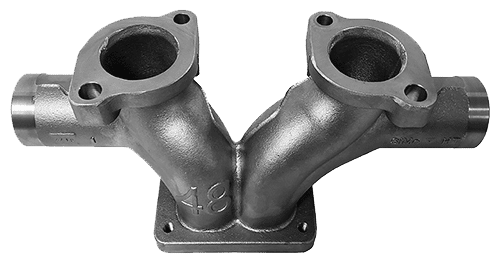

MTU Cylinder Liner Takeover

- MTU approached BNC to produce DDC 2-cycle cylinder liners.

- Their supplier at the time was less then 10% for on-time deliveries, with quality rejections of ~20%.

- BNC was awarded the program and launched 143 part numbers in 2009.

- Process includes milling, turning, centerless grinding, honing, brushing, classification, and management of two outside heat treat processes.

- Since launch, BNC has produced more than 750,000 liners, with a PPM of 2.7.

MTU Cylinder Liner Takeover